IoT Top News: Future is Now

The Internet of Things (IoT) is creeping into every aspect of our lives. With the advent of smart cities, smart manufacturing, precision agriculture, drones and digital energy, businesses and individuals alike have seen the influx of IoT technology. For example, a recent report from Gartner, “suggests that more than 26 billion devices will be connected to the internet by 2020, with 250,000 of them being vehicles.” So, with the billions of connected things, its only natural this week’s top news roundup would highlight how IoT is maturing and what experts see for the future ahead. Research Firm calls for Standardized IoT Deployments As the demand increases to make more smart cities, researchers warn of extra costsand fragmented delays if we don’t create overall IoT standards. Machina Research reports, “Using current non-standardized technologies, it would cost 1.12 trillion dollars to get smart cities up and running by 2025. Were a standardized approach adopted, the total cost would be 781 billion dollars, a savings of 341 billion dollars worldwide.” Is Automation the Key to Unlocking IoT Data? The best approach to implementation is a combination of data analytics with real-time automated wireless results Dave McCarthy senior director of products at Bsquare suggests that, “The goal of any IoT system should be to extract business value from device and sensor data.” Three Ways to Leverage IIoT Some of best ways to leverage Industrial IoT is by learning to adapt machine learning(M2M), embedded sensors and an overall operational shift allowing the wireless technology to be implemented across the business. Scott Stone with Plant Engineering informs us that, “Accenture predicts that vendor-specific and proprietary infrastructure will be replaced over time with interoperable platforms. Harnessing the data through sensor-driven computing, industrial analytics and intelligent machine applications opens the door for innovation.” Internet of Things Offers Vision of the Future IoT is not a new concept, it has actually been around for 30 to 40 years, yet the future of IoT will still be fueled by security and integration concerns as our need to be connected everywhere continues to grow. Basher Saajid with Liberty Voice reminds us that, “Forbes has reported the overall IoT potential to generate additional $10-$15 trillion for the world GDP by 2034.” We hope you enjoyed this quick look at IoT top news, as always tell us about the stories you found of interest!

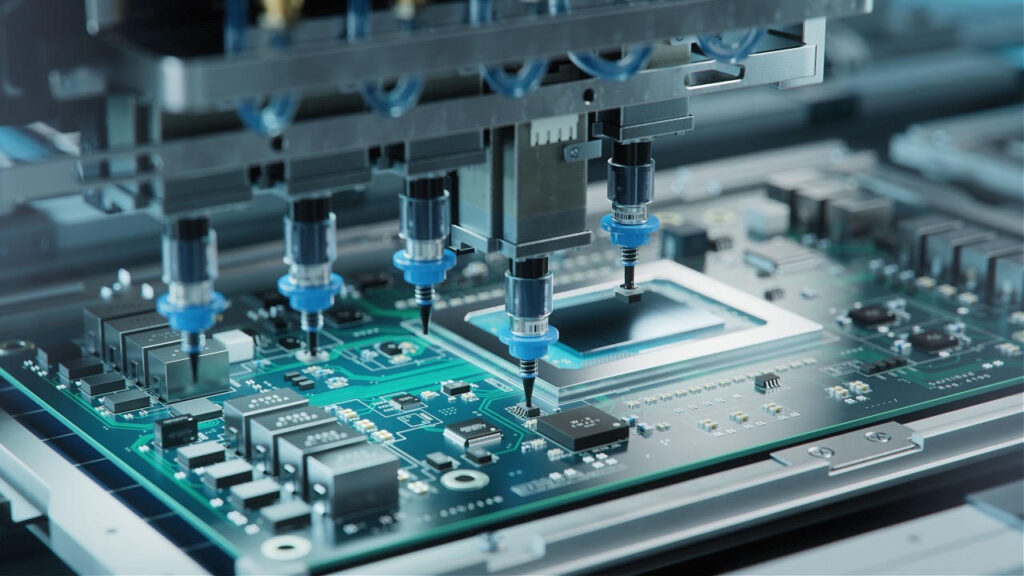

Top News: Manufacturing the Fate of Our Digital World

Manufacturing is in the midst reinventing itself on the heels of the latest IoT innovations. The industrial automation paradigm, which some say also gave rise to the lean manufacturing management philosophy, continues to influence organizations that wish to find new ways to capitalize on business opportunities in the digital age. Through that lens we gathered the top articles from the week and found some interesting perspectives. Some reports started suggesting manufacturing is in a time of trouble, both in the U.S. and around the globe, namely in places like China. But upon further investigation, we also find exciting trends that are shaping the evolution of manufacturing. We hope you enjoy this week’s roundup, and be sure to comment on your top articles of the week below! Chinese manufacturing fall adds to evidence of sharp global downturn (The Guardian) As the world watches Chinese manufacturing slow, many believe this is evidence of a major global downturn. The Guardian reminds us all that, “In another sign that manufacturers are braced for a long period of chasing business from a diminishing number of customers, they continued to lower their prices in February.” American Manufacturing in Peril (U.S. News) Gone are the golden days of domestic manufacturing, analysts now believe American manufacturing is in serious trouble. Andrew Soergel with U.S. News suggests that part of the problem for manufacturing is that, “The job market has changed. The generation has changed. The skill requirements to work in factories have changed.” The Manufacturing Side of CPG’s Digital Disruption (Automation World) In this era of digital disruption, consumer buying behavior will impact manufacturing practices. According to Stephanie Neil with Automation World, she thinks manufacturing could benefit from, “The use of standardized, reusable software modules simplifies configuration of robotic movements and integration with machine control functions. This allows machine builders to focus on increasing machine performance, added functionality, and equipment energy efficiency.” Despite all this talk about downturn and disruption in the manufacturing industry, there are some positive trends we should mention as well. Top 10: Manufacturing Trends of 2015 (Manufacturing Global) IoT, nanotechnology, SMAC Stack and greater visibility were all key manufacturing trends last year. According to Manufacturing Global’s trends, “Additive manufacturing, or 3d printing, is big news in the manufacturing sector. The new technology has captured the imagination of the general public and manufacturing executives alike, however it has also proven to be a game-changer for the industry.” 3-D Printing Poised to Shake up US Manufacturing (New York Post) In the last year 3-D printing has shown up in the medicine cabinet, operating rooms and even New York Fashion week. U.S. Manufacturing is getting a serious shake up with the launch of more 3-D printers. Catherine Curan with New York Post states that, “The 3-D printing boom isn’t big enough to single-handedly revive local manufacturing, but it will help.”

IIoT Top News: 2015 News Round-Up

Let’s take a moment and appreciate the excitement 2015 brought for the IIoT: As we look back at the top articles from the year, we were intrigued to learn that cooperative utilities actually have the largest penetration of smart grid meters per percentage of customers, according to Greentech Media and the U.S. Energy Information Administration. It’s interesting to see the largest publicly-owned utility companies in the U.S. are not the leader in deploying smart meter systems. Another topic that caught our eye this year focused on big data initiatives and how they will improve operational efficiencies by the large-scale storage and transfer of volumes of information safely and securely. Companies don’t always see the value in updating information governance policies because there isn’t always a direct reward and no direct penalty for non-compliance. Tim Jennings, Ovum chief research officer, believes as big data continues to grow within the company infrastructure, it is time to consider the security, availability, and time spent storing data. Speaking of Big Data… It is hard to grasp the magnitude of data transferred throughout the cloud. Today, as big data goes to work, it is transforming industrial facilities, and as Forbes states, “they have grown increasingly complex and yes, every machine, every pipeline, every transmission point collects data ready to be read.” Of course, a 2015 news review would not be complete without at least one mention of unmanned systems. Whether the want/need was for industrial, commercial or government applications, the thing on everyone’s mind was how many cool ways this technology could be deployed in the future. While there were many examples to choose from, DARPA certainly caught a lot of attention from its new autonomous submarine-hunting ocean drone. Yes, you read that right! Finally, as we ease our way into 2016, we would like to share the rest of the top technology and IIoT stories from 2015. This year’s round-up highlights articles about: utilities, manufacturing, oil and gas, wireless, big data, security, drones and industry analyst perspectives. Hope you enjoy this week’s roundup, and as always, tell us what we missed! Energy Six Ways IoT Enables Innovation in the Energy Industry (IT World Canada) The energy industry is learning to use IoT to its advantage. IT World Canada details six ways IoT is enabling innovation and improving overall cost and efficiency for the industry. Yogi Schulz with IT World Canada believes that “Applying these IoT advances to a range of energy industry problems will be a major factor in helping the industry return to profitability in the new, lower commodity price environment through innovation based on better data.” Manufacturing Machine Learning (The Economist) As manufacturing becomes digitized, the industry has to adjust from being a product-focused world to a services market, with smart machines installed on the shop floor. The Economist believes that “For many manufacturers—in Germany and beyond—the principal sticking-point in making this digital leap is often cultural.” Manufacturing’s Digital Future (Industry Week) The digital future of manufacturing will incorporate the data analytics, cloud and many other wireless IoT solutions. Industry Week believes “many companies are leveraging interconnectivity to improve their own factory productivity, the factory-floor blocking and tackling of reducing downtime, cutting costs, reducing cycle time, improving OEE, etc.” Oil and Gas In the Digital Oilfield, “No Wires is a No-Brainer (World Oil) With the digital progression of our world, it seems only fitting we would find IoT in the oilfield. The question we must ask is: “Why, in 2015, has wireless I/O not overtaken hardwired infrastructure as the industry standard throughout the OFS sector?” Big Data Internet of Things Transforming Oil and Gas Operations (RigZone) Analytical movement has increased as the cost of oil continues to drop, therefore forcing the oil industry to gravitate toward more big data and IoT. It has been said, “the amount of data generated by oil and gas operations is starting to explode as real-time information from sensors is being collected at a rate of four milliseconds.” Wireless Tech Darpa’s RadioMap Detects RF Spectrum Congestion (GCN) An interconnected connected wireless world has created congested airways, thus making military communication and intelligence gathering requiring radio frequencies be managed. “RadioMap adds value to existing radios, jammers and other RF electronic equipment used by our military forces in the field,” said John Chapin, DARPA program manager. Big Data The Ethics of Big Data (Tech.Co) Big data has been defined as information that has been either unstructured or multi-structured as way to transform data into value. Once you have given value to the data, it is important to realize who owns the data. Tech.CO says that “when it comes to big data ethics, privacy is not necessarily dead, shared information can still have a reasonable degree of confidentially, but big data can still compromise identity and other information that customers and businesses prefer to be confidential.” Security IoT Security Needs to Stop Being an Afterthought (PCR) In the age of smart homes and smart devices it is time to improve the IoT security across the board. The Internet Society (ISOC) recently released a white paper stating, “the vendors who use IoT should take more responsibility for the security issues that can occur with IoT products.” Drones Robo-Bulldozers Guided By Drones Are Helping Ease Japan’s Labor Shortage (The Verge) Komatsu had to find a way to complete construction projects, as Japan gets closer to the 2020 Olympics. The aging population makes it hard to find anyone able to complete the work. The fix Komatsu has found is to offer a service called Smart Construction where, “a team of robotic vehicles scoops rock and pushes dirt without a human behind the wheel. They are guided in their work by a fleet of drones, which map the area in three dimensions and update the data in real time to track how the massive volumes of soil and cement are moving around the site.” Deforestation: British Firm Developing Tree-Planting Drone to Counter Industrial-Scale Logging (The Independent) A British engineering company is hoping to get international backing for an automated tree planting drone system. The purpose of these drone planting fleet’s, would be not

IIoT Bold Prediction Series Part 5: Discrete RF Manufacturers Obsolete in Three Years

What a week it has been for the connected world! As we grow closer to the end of 2015, there are plenty of movers and shakers in the IoT space, and for good reason – the excitement around the industry is palpable. In fact, it’s hard to keep a pulse on all the activity as there seems to be innovations occurring daily. Additionally, the IoT provider ecosystem itself continues to grow rapidly as the influx of companies – from device manufacturers and software vendors to IT and Cloud services as well as industry groups and regulators – continue to push the bounds of possibility not just for consumers, but businesses as well. To further add to the end of year developments in IoT, our 2016 IIoT Bold Prediction Series ends the week with a bang – after all, it’s not every day that the CEO of a company predicts the demise of its own industry! However, Kim Niederman, CEO of FreeWave Technologies, is making the bold prediction that discrete Radio Frequency (RF) technology manufacturers will be obsolete within the next three years. Prediction #5: The obsolescence of discrete RF manufacturers will occur by 2019 The catalyst that will drive this change will be the open standards in place that will eventually commoditize the market by bringing backwards compatibility and interoperability between different radio manufacturers. Large chip manufacturers are going to drive physical layer standards, meaning the chipsets themselves are going to be more ubiquitous and will make it increasingly difficult for discrete radio manufacturers to find and capitalize on business opportunities in the marketplace. Companies will continue to drive the adoption of open standards and the concept of the software-defined radio will soon become meaningless. Stay tuned for more on this bold IIoT prediction!

IIoT Top News: Manufacturing Today and Tomorrow

The age of manufacturing is moving past the dusty, oversized, broken-down warehouse located on the edge of town and into industrial 4.0. This new technological revolution is changing the way manufacturing operates within the digital sphere. Nowadays, manufacturers can track production status, machine functionality and operational flow with sensors, automation and wireless IIoT solutions. That’s why this week’s top news is dedicated to manufacturing of today and tomorrow, realizing this industry is evolving with the digital revolution. This is an exciting time for manufacturing, with more innovation integration happening across the board than in the last twenty years. As the IIoT starts to take center stage in many shop floors, new digital upgrades will require a new plan of action to deploy wireless pilot projects for automation and control. Now with the rise of smart machines in manufacturing, this industry has to shift from a product oriented world to a services market. Sensors that tell you why it is not working or machines ordering products independently when supplies run low are all examples of this new industry 4.0 revolution in action. Naturally this technological movement began in Germany back in 2011, where twenty-two percent of their GDP comes from manufacturing, this compared to only twelve percent of the GDP in the US. Although, a recent report by Cisco finds that the majority of manufacturers are not capitalizing on this digital push. It is true most manufacturers do see the importance of the digital transformation on their shop floors, but the problem comes with the implementation of those new technologies without disrupting the current production process. As manufacturers digitize, it is vital to first find the correct infrastructure to implement the IIoT, and then to adapt a new model to incorporate the technology to the main business plan. So what does the future hold for manufacturing? As some companies adapt to this digital age, it is true manufacturing can now create digital prototypes, use 3D printers and operate remotely with sensors and wireless monitoring. Being able to collect data in real-time utilizing cloud-based IIoT solutions will be the key to succeeding in manufacturing going forward. Yet, according to Information Age 2016 top predictions, “Manufacturers will have to start thinking and acting more like software companies, leveraging the software applications they build into their products as a driver to reduce manufacturing costs, increase product innovation, and capture new revenue streams.” Furthermore, IoT, data analytics, cloud, and other wireless technologies have the potential to drastically improve manufacturing. The trick, as we march to the beat of this new technological revolution, will be to look at examples of how early adaptors have grasped the IIoT. It’s understandable with everyone shouting about the IIoT, it is easy to get overwhelmed. So stop thinking about all things connected and focus on what infrastructure will support your growing digital needs on the shop floor, and then your plan of action will seem a bit more manageable. Hope you enjoy this week’s reading. As always, tell us what we missed! Enabling Manufacturing Transformation with the IIoT (PTC) This push for IIoT is transforming the way manufacturing operates and functions as a whole. PTC suggests that, “As these innovations and pilot projects begin to emerge as broadly deployed best practices, the industry will start to see the emergence of business model transformation and the visions of Industries 4.0 and Smart Manufacturing will start to become a reality.” Machine Learning (The Economist) As manufacturing becomes digitized, the industry has to adjust from being a product focused world to a services market, with smart machines installed on the shop floor. The Economist believes that, “For many manufacturers—in Germany and beyond—the principal sticking-point in making this digital leap is often cultural.” Survey: Manufacturers’ Digital, Service Capabilities Lagging (Manufacturing.net) Manufacturers see the need for adding more digital components to the shop floor, but recent CISCO report finds that many manufacturers are still not capitalizing fully on the IIoT. “One challenge is on the technology side, making sure that the right infrastructure is provided,” said Dirk Slama of Bosch Software Innovations. “The second challenge I would see is more on the organizational level, to make sure that you somehow help your organization move towards these new business models.” The Factory Future (Manufacturing Today) The future of manufacturing will depend on the industries abilities to incorporate real-time results with their wireless IIoT solutions. Manufacturing Today has stated that, “More manufacturing will need to be able to harness all that data via the cloud to meet demands from customers and potentially legislators to fully track the entire lifecycle of their products—from creation to disposal of ideally recycling.” Manufacturing’s Digital Future (Industry Week) The digital future of manufacturing will incorporate the data analytics, cloud and many other wireless IoT solutions. Industry Week believes that, “Many companies are leveraging interconnectivity to improve their own factory productivity, the factory-floor blocking and tackling of reducing downtime, cutting costs, reducing cycle time, improving OEE, etc.