IoT Top News: Manufacturing Disruption

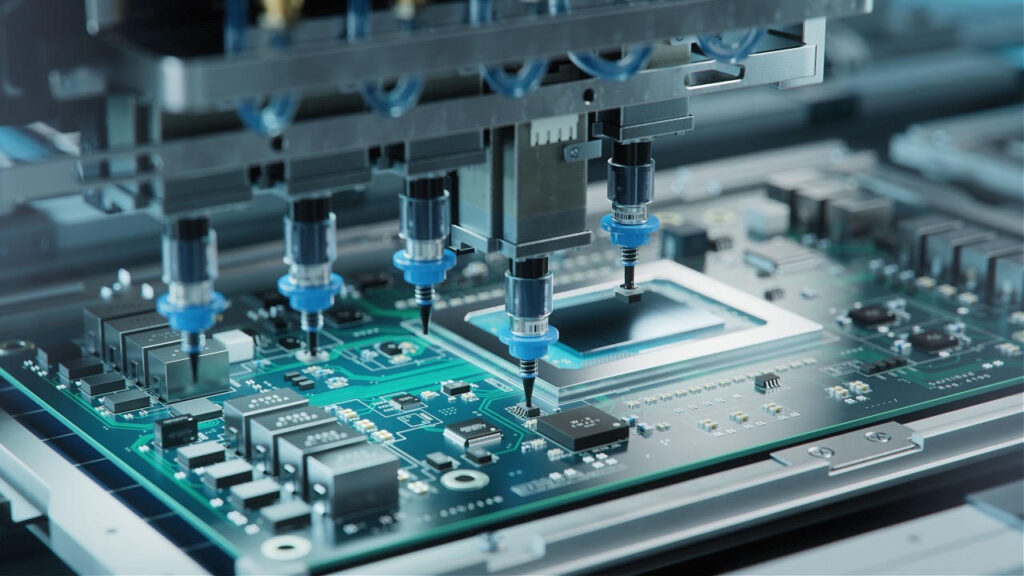

Industrial IoT continues to cause disruption; not just in manufacturing, but across many other industries as well. In the last few months we’ve been keeping a pulse on the state of digital transformation across the business landscape and have been discovering exciting new implementations of Industrial Internet of Things (IIoT). This week we’re highlighting the disruption Industrial IoT is instigating as product development and lifecycle management continues to evolve. Overcoming Three Key Barriers to Industrial IoT Industrial IoT has the potential to capture data in real-time, leverage big data analytics and streamline efficiency to name a few. So what’s hold back the industry? A major barrier has to do with culture of the operational technology (OT) organizations within the industry. The OT have a risk-averse way of thinking and see change as disruption, “Whereas IT is defined by constant change and innovation, that’s why it’s not unusual to see industrial automation systems in service for decades at a time with little or no change.” Bringing Smart Technology to Old Factories Can be an Industrial-Sized Disruption It sounds amazing to have robotic arms working together with the Industrial IoT. The reality is manufacturing is being disrupted by the implementation of IIoT. Mary Catherine O’Connor with the Wall Street Journal reminds us that, “Often plant managers can’t tell which sensor will most accurately collect the data they want from a machine without a series of test runs—a time-consuming process.” Product-Development Strategies in the IIoT Disruption The key to succeeding with IIoT disruption will be to focus on the new innovation of both product and software for the industry. Machine Design reminds us that, “IIoT is a disruptive force that will shape product-development trends over the next decade and beyond.” Relying on CMM to Keep IIoT’s Disruption Positive All the talk up to this point has been about the negative disruptive impacts IIoT is having on the industry. IIoT has the ability to drastically change manufacturing with a positive level of disruption introduced on the shop-floor. According the the American Machinist positive disruption can happen, “By using coordinate measuring machinery (CMM), machine shops or other manufacturers are able to capture the precise details of the geometry or surface conditions of a workplace. Working within IIoT, those manufacturers then are able to share such data between machines, exchange information between facilities, or with customers or suppliers.” Now we would like to leave you with this quick excerpt from Kevin Ashton, a British technology pioneer who co-founded the Auto-ID Center at the Massachusetts Institute of Technology (MIT) and inventor of the term “the Internet of Things.” How the Internet of Things Disruption Gains Traction – Extreme IoT We hope you have enjoyed this closer look at the disruption Industrial IoT is bringing to the table and what steps are being done to allow more implementation across the industry. Let’s us know what disruption you have seen with IIoT.

Internet of Things Expo: What to expect this week

The Internet of Things (IoT) is essential for both enterprise and personal, everyday use. Leading research firms agree that IoT will experience an unbelievable boom, possibly into the tens of billion devices by 2020 as computers, smartphones and sensors all require connectivity. This week’s Things Expo is a SYS-CON Media annual event, designed to help make sure your enterprise is IoT-ready with 80 breakout sessions focusing on many aspects of IoT, including big data’s use with predictive analytics, smart grid and Industrial IoT (IIoT), wearables, identity in IoT and modem data centers, among many other tracks. Here is a sneak peek at keynote Internet of Things Expo speaker Chris Matthieu. Also…Check out this clip of a Things Expo Power Panel It is going to be an action-packed three days of IoT information dumps from the experts. If you have the chance to be in New York this week, be sure to check out this conference and soak up some knowledge. Scott Allen, CMO of FreeWave, will be presenting “Sensor-2-Server: Intelligent Communication at the Access Layer” at ThingsExpo on Tuesday, June 7th from 4:40 – 5:15p.m. EDT. (http://www.cloudcomputingexpo.com/event/session/3238). Sensor-2-Server™ (S2S™) intelligent communications for the access layer can collect and transport the data that supports higher-level analytics. As IoT becomes adopted by industrial markets, there is going to be an increased demand for video, voice, data and sensor data communication from the outermost layer of the network. Let us know what you think. Which aspects of IoT are most interesting to you? What needs more coverage and information?

IoT Top News: M2M Propels Machines

Time and again, those keeping a pulse on the Internet of Things (IoT) space frequently hear about the “rise of the machines.” Humanity is not only discovering fascinating ways to integrate machines into our daily lives, but also finding new uses for machines as well. How? Machines are now “internet-connected” just like the smartphones we carry around in our pockets. And this isn’t just on the commercial side with the likes of smart thermostats or connected vehicles – even tractors and oil and gas machinery are industrial examples of where new “things” are now on the digital network. In fact, there are more M2M or “machine-to-machine” communication devices on this planet than humans. As GSMA Intelligence reported in 2014, there are 7.2bn M2M devices versus 7.19bn humans. Stuart Taylor from Cisco also wrote a prediction that “The Internet of Things (IoT) is a world where up to 50 billion things (or devices) will be connected to the Internet by 2020; or, the equivalent of 6 devices for every person on the planet.” Realizing the major role M2M devices continue to have in our connected world, specifically as it relates to the advent of machine learning, it’s only natural to highlight the impact of machines and M2M in the past, present and future. The Machines are Coming: How M2M Spawned the Internet of Things In the digital world, M2M wireless solutions will work for us quietly, in the background solving all our day-to-day needs. John Kennedy with Silicon Republic reports that, “M2M is at the heart of the industrial internet of things (IIoT), powering smart factories that can be run remotely from a tablet computer, and smart buildings that monitor their environment and feed data back to the cloud.” Is Machine Learning Over Hyped? In the now 24-hour news cycle, often the top news lingers around lighter topics. So how much hype should be given to machine learning (ML)? The Huffington Post respondent Scott Aaronson, theoretical computer scientist at MIT, seems to think that “There’s no doubt in my mind that people 30 years from now will agree with us about the central importance of ML, but which aspects of ML will they rage at us for ignoring, or laugh at us for obsessing about when we shouldn’t have? Machine Learning: Demystifying Linear Regression and Feature Selection Machine learning needs to integrate domain knowledge in order to improve the quality of data collected from analysts. Josh Lewis with Computerworld thinks that, “Business people need to demand more from machine learning so they can connect data scientists’ work to relevant action.” Machine Learning Examples Crop up for Data Center Management Data centers appear to be the perfect place for enterprises to implement machine learning to its fullest. Christopher Yetman, COO at Vantage Data said, “There are also sensors that generate data about air pressure, humidity, temperature and supply voltage and typically feed into a programmable logic controller.” M2M Technology Driving Agriculture’s Industrialization On a global front, M2M is driving agriculture’s industrialization in South Africa. IT News Africa informs us that, “Given the ability to automate many monitoring and control functions through intelligent devices, agriculture is a prime target for leveraging M2M capabilities.” We hope you have enjoyed this week’s roundup, and as M2M connections continue to pile-up, we urge you to consider the plethora of commercial and industrial use cases that can benefit from these innovations.

IoT Top News: Future is Now

The Internet of Things (IoT) is creeping into every aspect of our lives. With the advent of smart cities, smart manufacturing, precision agriculture, drones and digital energy, businesses and individuals alike have seen the influx of IoT technology. For example, a recent report from Gartner, “suggests that more than 26 billion devices will be connected to the internet by 2020, with 250,000 of them being vehicles.” So, with the billions of connected things, its only natural this week’s top news roundup would highlight how IoT is maturing and what experts see for the future ahead. Research Firm calls for Standardized IoT Deployments As the demand increases to make more smart cities, researchers warn of extra costsand fragmented delays if we don’t create overall IoT standards. Machina Research reports, “Using current non-standardized technologies, it would cost 1.12 trillion dollars to get smart cities up and running by 2025. Were a standardized approach adopted, the total cost would be 781 billion dollars, a savings of 341 billion dollars worldwide.” Is Automation the Key to Unlocking IoT Data? The best approach to implementation is a combination of data analytics with real-time automated wireless results Dave McCarthy senior director of products at Bsquare suggests that, “The goal of any IoT system should be to extract business value from device and sensor data.” Three Ways to Leverage IIoT Some of best ways to leverage Industrial IoT is by learning to adapt machine learning(M2M), embedded sensors and an overall operational shift allowing the wireless technology to be implemented across the business. Scott Stone with Plant Engineering informs us that, “Accenture predicts that vendor-specific and proprietary infrastructure will be replaced over time with interoperable platforms. Harnessing the data through sensor-driven computing, industrial analytics and intelligent machine applications opens the door for innovation.” Internet of Things Offers Vision of the Future IoT is not a new concept, it has actually been around for 30 to 40 years, yet the future of IoT will still be fueled by security and integration concerns as our need to be connected everywhere continues to grow. Basher Saajid with Liberty Voice reminds us that, “Forbes has reported the overall IoT potential to generate additional $10-$15 trillion for the world GDP by 2034.” We hope you enjoyed this quick look at IoT top news, as always tell us about the stories you found of interest!

IIoT Top News: Industrialized

As machines are increasingly connected to the internet, it’s becoming easier to discover the numerous ways Industrial IoT (IIoT) is helping to shape the business world. This is exactly why we have decided to take a closer look at this pervasive movement and to examine the desire to connect more things! Now if you need a refresher on IIoT and how it is changing the world, take a moment and listen to Greg Gorbach with ARC Advisory Group. Gorbach believes, “IIoT will significantly change the world. You won’t participate with conventional thinking and an incremental approach.” So, you understand some of the ways IIoT will vastly improve how businesses function. But did you realize IIoT is more than just connected devices and smart machines? George Deeb with Forbes reminds us that IIoT impacts manufacturing, energy, oil and gas, healthcare, IT and much more. Deeb reports that, “Gartner predicts the IoT industry to be $1.9TN in size by 2020, and McKinsey thinks it could be as large as $6.2TN by 2025, in terms of economic impact.” Are we ready for it? Although the industry has excepted the new buzzword “IIoT” we still need to make sure the equipment and software are able to interact together or we are just adding more problems to the mix. Maria Ferrante at Packing World informs us that, “The Industrial Internet of Things has moved into the pantheon of 21st-century packaging buzzwords alongside RFID and Sustainability.” Alright! So how is IIoT changing the oil and gas industry? The Oil and Gas industry has seen an increase demand for more of wireless cloud IIoT technology and M2M solutions as the price of a barrel of oil dips down to a new all time low. Live Mint reminds us that, “Oil and gas companies are increasingly leveraging cloud technologies to more rapidly unlock the value of other digital technologies—especially analytics, IoT and mobility.” That’s all for this week’s recap, but there’s more! Now that we are into the beginning of Spring, it’s important to see how some of the 2016 IIoT predictions are shaping up. In case you have any thoughts on our IIoT predictions for 2016 (or have any new predictions your own), it’s not too late to iterate on them into the comments section below!

Robots Will Steal Your Future Paychecks

We’ve spent many words on this blog talking through new Industrial IoT technologies, hardware and software, and the way that the status quo has shifted to demand better connectivity, smarter infrastructure, and better access to real-time data across the spectrum. Where we haven’t spent much time is considering the economic impact these technologies will have on the average person. Without looking too far into the future, we can already see the impact of a more automated workforce. With that in mind, and on top of all our other daily worries, do we need to be worried about robots stealing our paychecks in the future? Eric Brynjolfsson, recently presented a TED Talk about this very topic, but unlike the sci-fi fear mongers, Eric had a different approach. Brynjolfsson suggests we stop trying to compete with machines and focus in on how they can complement our work-life. It’s true today it takes less people to get the job done. This shift to automation is forcing companies to rethink infrastructure and think more about speed, efficiency and overall time. This isn’t the time to reinvent the wheel, it’s time to think about how that wheel can be tweaked to operate more smoothly and consistently over time. Now, before you let your imagination run wild of a robot powered world, that will be lucky to be apart of, take a moment and watch Brynjolfsson’s TED Talk. Not to worry there is still hope, you may not have to hand over your paychecks to tomorrow’s robots, just yet!

First Responders: Saving Lives, Time and Money Through Innovation

How the Internet of Things is Changing the Landscape for First Responders and Industry According to the National Fire Protection Association, in 2013 there were 369,500 home fires causing some $6.8 billion in damages1 — plus an additional 98,000 apartment structure fires contributing an additional $1.6 billion in losses2. A frightening picture, isn’t it? The numbers are staggering — and yet innovation for emergency responders at both a local and national has not been a priority. The Internet of Things (IoT) aims to change that. Companies are now exploring how IoT technology can disrupt the way emergency responders do their jobs, saving countless lives and millions of dollars in the process. The IoT also holds immense promise for industrial applications, which often take place in remote locations where connectivity and communication platforms are rarely available. The IoT is a vast world, enabling the physical world to communicate with the digital world in new and amazing ways. But thanks to innovations fueled by companies focused on industrial, military, and government applications, we can traverse beyond a network of connected thermostats and smart TVs into an environment where first responders, industrial crews, and our military can communicate and receive critical information in real time. An example of technology that is changing the world of emergency responders as well as industries like Oil and Gas, the Military, and Utilities are ruggedized, industrial shorthaul and Wi-Fi platforms that offer secure collection, control and transport of Voice, Video, Data and Sensor information at incredible speeds. So what does this mean for the industries mentioned above? Imagine first responders being enabled to pull up building plans and architectural details as they arrive on scene. Structural notes are delivered at incredible speeds, giving the emergency responders valuable insight into stairway and fire escape placements and potential danger zones. Communication between police, fire crews and ambulance drivers is streamlined — delivered at blazing fast speeds. In other situations, police can access vehicle databases or hospital services, preserving precious minutes than can mean the difference between life and death. For industrial applications, the IoT holds promise for new levels of connectivity — enabling crews to access and consume information at a moment’s notice. This means workers can collect and transmit important data quickly and securely — even in harsh conditions. Beyond connectivity, the Internet of Things also holds massive promise for the monitoring of emergency responders and industrial crews in the field. Critical sensor data — such as oxygen levels, body and ambient temperature, heart rate and more — can be viewed in real time, giving the ability to monitor the vitals of emergency responders and workers in an instant and watch for danger signs and track bio data in the field. This data can be logged and analyzed, fueling innovation that will help keep these employees safe. The IoT is a vast and ever-growing field — and it holds incredible promise for making our cities a better and safer place to live and work. For emergency responders, where seconds saved can be lives saved, and industries where time is money, the IoT holds remarkable promise for changing the way we communicate, gather data, and work in the field. ————- Sources: 1 – http://www.nfpa.org/research/reports-and-statistics/fires-by-property-type/residential/home-fires 2 – http://www.nfpa.org/research/reports-and-statistics/fires-by-property-type/residential/apartment-structure-fires

IWCE 2016: What to expect next week?

The International Wireless Communications Expo (IWCE), is an annual event for communication technology professionals working globally in a broad range of the communications field, including energy, utilities, emergency response and municipality/infrastructure. This conference will get under way next week, from March 21-25, in Las Vegas. An estimated 7,000 individual industry experts are expected to attend from government/military; public safety (law enforcement, fire service and first responders); utility, transportation and business enterprise. IWCE will also feature around 370 exhibitors ready to show you the latest product innovations and trends forecasted this coming year. Donny Jackson editor of Urgent Communications, the official tradeshow media partner, believes that this year’s IWCE will give industry professionals a chance to get educated about the latest critical-communications technology, all while making key network contacts with industry experts. So, what else can we look forward to? IWCE promises to offer engaging content–with their 5-day comprehensive conference program; more quality time with peers; industry experts providing the latest strategies and tactics; minimal expenses–when you take advantage of conference discounts; structured networking opportunities; tangible handouts you can use throughout the year; more face-to-face learning time and more educational opportunities will be available this year. Excitement is building! Here are just a few of the people and organizations excited for next week’s event! Tune in next week for our IWCE insider recaps. Vegas here we come!

Top News: Manufacturing the Fate of Our Digital World

Manufacturing is in the midst reinventing itself on the heels of the latest IoT innovations. The industrial automation paradigm, which some say also gave rise to the lean manufacturing management philosophy, continues to influence organizations that wish to find new ways to capitalize on business opportunities in the digital age. Through that lens we gathered the top articles from the week and found some interesting perspectives. Some reports started suggesting manufacturing is in a time of trouble, both in the U.S. and around the globe, namely in places like China. But upon further investigation, we also find exciting trends that are shaping the evolution of manufacturing. We hope you enjoy this week’s roundup, and be sure to comment on your top articles of the week below! Chinese manufacturing fall adds to evidence of sharp global downturn (The Guardian) As the world watches Chinese manufacturing slow, many believe this is evidence of a major global downturn. The Guardian reminds us all that, “In another sign that manufacturers are braced for a long period of chasing business from a diminishing number of customers, they continued to lower their prices in February.” American Manufacturing in Peril (U.S. News) Gone are the golden days of domestic manufacturing, analysts now believe American manufacturing is in serious trouble. Andrew Soergel with U.S. News suggests that part of the problem for manufacturing is that, “The job market has changed. The generation has changed. The skill requirements to work in factories have changed.” The Manufacturing Side of CPG’s Digital Disruption (Automation World) In this era of digital disruption, consumer buying behavior will impact manufacturing practices. According to Stephanie Neil with Automation World, she thinks manufacturing could benefit from, “The use of standardized, reusable software modules simplifies configuration of robotic movements and integration with machine control functions. This allows machine builders to focus on increasing machine performance, added functionality, and equipment energy efficiency.” Despite all this talk about downturn and disruption in the manufacturing industry, there are some positive trends we should mention as well. Top 10: Manufacturing Trends of 2015 (Manufacturing Global) IoT, nanotechnology, SMAC Stack and greater visibility were all key manufacturing trends last year. According to Manufacturing Global’s trends, “Additive manufacturing, or 3d printing, is big news in the manufacturing sector. The new technology has captured the imagination of the general public and manufacturing executives alike, however it has also proven to be a game-changer for the industry.” 3-D Printing Poised to Shake up US Manufacturing (New York Post) In the last year 3-D printing has shown up in the medicine cabinet, operating rooms and even New York Fashion week. U.S. Manufacturing is getting a serious shake up with the launch of more 3-D printers. Catherine Curan with New York Post states that, “The 3-D printing boom isn’t big enough to single-handedly revive local manufacturing, but it will help.”

Sensor-2-Server: Benefits & Security for IIoT Communications

*This is part of a series of blogs examining Sensor-2-Server (S2S) communications, development, security and implementation. For the past two weeks, we’ve taken an in-depth look at what Sensor-2-Server communications are, how to implement these systems, and some of the specific aspects of communication that these systems facilitate. This week, for our final installment, we’ll examine some of the benefits, as well as security considerations, for S2S communications. Benefits of Sensor-2-Server Communications From a technology partnership perspective, Big Data vendors face the challenge of comparing data in motion versus data at rest. If the data has already moved through a SCADA system and has been aggregated, changed, stalled, or is not quite granular enough, it can be difficult to deliver high-value predictive analytics. The concept of predictive analytics is that an operator can make an accurate estimate that certain things can happen during operations. However, the operator needs to determine what the drivers are for the predicted actions to happen and must look at active data to determine if this is, in fact, happening. Without insight into the active data in motion, they are lacking an essential piece of the predictive analytics. This ability to compare data in motion at the access layer could benefit Big Data vendors when it comes to predictive analytics because it allows them to give higher value to their customers, which drives additional revenue. With S2S technology, they can deploy a tiered application infrastructure that allows data to intelligently move from one point to another. S2S also enables operators to go beyond a legacy SCADA data network. To operate a SCADA network, it requires a lot of institutional knowledge to truly understand, manage and work within the environment. S2S expands beyond moving the data into SCADA systems and allows operators to leverage more advanced technology, like predictive analytics. Essentially, S2S communications provide the opportunity to take advantage of new advanced tools, but the operator doesn’t necessarily have to sacrifice the institutional knowledge built into the SCADA data systems. As new generations enter the workforce, it’s likely that there will be a shift and some of that institutional knowledge will be replaced with technology that will allow operators to do more than they ever could before. The addition of new technology and IoT networks is where operators are starting to see the functional lines blur between the IT and production groups. As more technology is leveraged, these two disparate groups will have to work together more often. There is now a drive for a more holistic picture of what is going on in IT, what is going on in the field, and whether the technology used will be compatible with future needs. SCADA will likely always have value for industrial communications but, going forward, there will be an increase in the use other technologies as well. Additionally, with more technology physically in the field, there is always going to be a focus on data security. Security Sensors at the access layer present interesting security challenges. For example, consider a data concentrator sitting on an oil pad that is collecting data. This device is collecting data from a number of sensors and has data logging capabilities, which also means the other devices sitting at the remote site contain historical data. Technology providers need to insure that the technology used is taking advantage of all the security features that are available to make sure their data is protected through a variety of means including encryption, authentication, virus and intrusion protection, and by being physically tamperproof. With the growing interest in IIoT, the system is providing a communication path with highly valuable information. These sensors may be running an application on the edge of the network, and many of these devices are using IP. When there are Ethernet and IP devices going out to edge devices in the field, each one of those devices has the potential to become a threat to the entire corporate network if they’re not secure. Operators in IIoT environments need to be concerned with everything that could be introduced to the network at every single connection point. Data protection data is a fundamental and extremely important element in determining the effectiveness of S2S communication. Technology vendors must be mindful of security in every step of the design and installation process, and operators must require security features that will protect their data and networks. In addition to data security, the threat to physical infrastructures in very remote locations is driving the need for new security solutions such as intelligent video surveillance designed to maximize security and minimize cost. S2S solutions need to be physically capable of delivering the bandwidth to enable these new solutions. Where Do We Go From Here? Industrial communication is changing in the sense that IIoT enables the possibility for every device in a network to be connected – including those in the outer access layer. This has created a convergence of OT and IT operations in many instances or – at the very least – has brought the two departments to a closer working capacity. IoT and technology at the access layer enable the option for Sensor-2-Server, a form of intelligent communications that can move the sensor data to a specific server for detailed analysis. New data and technology are allowing operators to do things they’ve never done before, such as predictive analytics. As this shift continues, SCADA is not becoming an obsolete technology; rather it will become a piece in the bigger technology picture. Any operator choosing S2S technology, or any technology for that matter, must carefully consider the options and keep security as a top priority.